Oufu Optical Fiber Cable Co.,Ltd

Address: Shenyang, Liaoning, China

Contact person: Manager Zhang

Phone: 400-964-1314

Mobile phone: 86 13904053308

【whatsapp && wechat】

2025-09-17 1102

iunit risers cable forms the critical backbone of modern multi-tenant buildings, providing the essential connectivity that powers everything from internet services to security systems. These specialized cables are designed for vertical deployment through multiple floors, ensuring reliable signal transmission while meeting strict fire safety regulations. Interestingly, many building managers focus only on initial cost rather than long-term performance and compliance. Our team discovered this during a 2023 high-rise retrofit where improper cabling led to costly code violations and system failures. This guide reveals the key strategies for successful riser cable implementation.

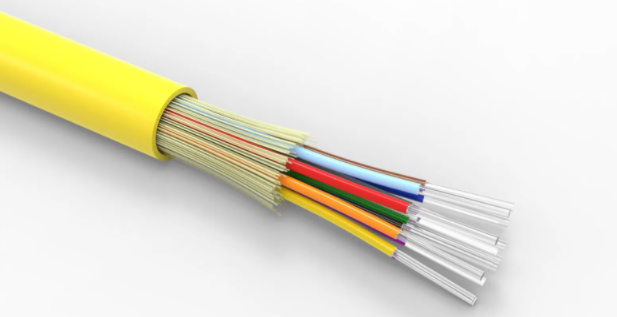

iunit risers cable forms the critical backbone of modern multi-tenant buildings, providing the essential connectivity that powers everything from internet services to security systems. These specialized cables are designed for vertical deployment through multiple floors, ensuring reliable signal transmission while meeting strict fire safety regulations. Interestingly, many building managers focus only on initial cost rather than long-term performance and compliance. Our team discovered this during a 2023 high-rise retrofit where improper cabling led to costly code violations and system failures. This guide reveals the key strategies for successful riser cable implementation.What exactly are multiunit risers cables? These are communication cables specifically engineered for vertical runs in building riser spaces - the shafts and conduits that run between floors. Unlike general-purpose cables, riser-rated cables (CMR rating) feature enhanced fire-resistant materials that prevent flame propagation between floors while maintaining signal integrity. Their construction typically includes superior insulation materials, higher temperature tolerance, and reduced smoke emission characteristics.

How do riser cables compare to other cable types? This analysis reveals crucial differences:

| Feature | Multiunit Risers Cable | Plenum Cable | General Purpose Cable |

|---|---|---|---|

| Fire Safety Rating | CMR (Riser Rated) | CMP (Plenum Rated) | CM (General) |

| Installation Location | Vertical shafts between floors | Air handling spaces | General areas |

| Flame Spread | Prevents vertical spread | Lowest flame spread | Basic resistance |

| Cost | Moderate | Highest | Lowest |

| Smoke Production | Low | Very Low | Variable |

Industry studies show that proper riser cable installation reduces fire-related incidents in multiunit buildings by up to 60% compared to non-compliant installations, making them a crucial safety investment.

Proper installation requires meticulous attention to these steps:

Step 1: Conduct a thorough site survey to identify appropriate riser pathways and verify compliance with local building codes. Measure exact distances and identify any potential obstacles or existing infrastructure conflicts.

Step 2: Select the appropriate cable type based on the specific application - whether for fiber optic communications, security systems, or power-limited signaling. Ensure all cables carry proper CMR certification for riser applications.

Step 3: Use appropriate pulling techniques with tension monitoring to prevent damage to the cable structure. Never exceed the maximum pulling tension (typically 100-300 pounds depending on cable type) and maintain proper bend radius (usually 20x cable diameter).

Step 4: Install fire-stop systems at each floor penetration using approved materials and methods. These barriers are essential for maintaining the fire integrity of the floor assemblies and preventing smoke spread.

Step 5: Test all installed cables for performance characteristics before commissioning. For fiber optics, use OTDR testing to verify signal integrity; for copper cables, perform transmission testing to ensure proper connectivity.

⚠ Critical installation warnings:

Never use non-riser rated cables in vertical shaft applications

Avoid mixing different cable types in the same riser without proper separation

Ensure all fire-stop installations meet local building code requirements

Never exceed cable bend radius specifications during installation

Selecting the right riser cable involves several key considerations. The cable must carry appropriate safety certifications (UL CMR rating) for your region. Consider the number of conductors or fibers needed both for current requirements and future expansion. Jacket material should be suitable for the installation environment - moisture-resistant for damp shafts, sunlight-resistant for outdoor risers. For high-rise buildings, consider cables with superior tensile strength to withstand vertical hanging stresses.

These cables are particularly essential for modern smart buildings where they serve as the central nervous system, carrying data for internet services, telephone systems, security monitoring, building automation, and entertainment services. Their performance directly affects the quality of service for all building occupants.

The future of riser cabling is evolving with technological advancements. Newer cables now incorporate higher bandwidth capabilities, better fire performance characteristics, and improved durability features. The trend toward fiber optic riser cables continues to grow as bandwidth demands increase and costs decrease.

Checklist for successful riser cable deployment:

Verify all cables carry proper CMR certification

Confirm compliance with local building codes and regulations

Ensure proper fire-stop materials and methods are available

Plan for adequate cable support in vertical runs

Arrange for proper testing and certification of installed systems

Frequently Asked Questionswww.adsscable.cn

Q: Can plenum-rated cable be used in riser applications?

A: Yes, plenum-rated (CMP) cable can be used in riser spaces as it exceeds riser rating requirements, though it comes at higher cost.

Q: How often should riser cables be inspected or replaced?

A: Most quality riser cables have a lifespan of 15-20 years, but should be inspected every 5 years for damage or degradation.

Q: Can different types of riser cables be bundled together?

A: Generally yes, but always check local codes and maintain separation between power and low-voltage cables as required.

Q: What's the maximum height riser cables can be installed without intermediate supports?

A: Most codes require support every 100 feet vertically, but consult specific cable specifications and local regulations.

Q: Are there special considerations for seismic zones?

A: Yes, in seismic areas additional cable slack, flexible connections, and specialized support systems may be required.